Nature Sciences

BIT Publishes an Important Review Article on "Kirigami/ Origami: Unfolding a New Chapter in 3D Microfabrication/ Nanofabrication"

Modern technology extends the concept of paper-cutting, one of the ancient Chinese traditional folk arts, developing it into a unique deformation science and technology. Recently, Professor Li Jiafang, School of Physics, Beijing Institute of Technology and Professor Li Zhiyuan, South China University of Technology have collaborated on the principles and methods of the new three-dimensional microfabrication/ nanofabrication technology of kirigami/ origami in recent years, as well as the realization, application, challenge and development trend of two-dimensional planar materials and structures at the microscale/ nanoscale of three-dimensional deformation, which were fully introduced and discussed in depth. The long review paper has been published in the optical authoritative journal Light: Science & Applications (IF: 14.523).

High-precision three-dimensional microfabrication/ nanofabrication is an important foundation for the establishment and development of contemporary information technology. Among them, top-down "subtractive manufacturing" and bottom-up "additive manufacturing" approach covers almost the entire precision manufacturing field. In recent years, attention of the three-dimensional kirigami/ origami technology has been paid in the fields of mechanics, microelectronics, acoustics, optics, etc because of its unique manufacturing method. The biggest feature of this technology is that the quality of the material itself hardly changes during the three-dimensional reconstruction, neither "additive" nor "subtractive", and the space occupied by the structure can be changed by several orders of magnitude by the geometric transformation, which implies a profound scientific transformation idea. Professor Li Jiafang and the cooperative team invented a three-dimensional microprocess/ nanoprocess technology based on nanokirigami in 2018 [Science Advances 4, eaat4436 (2018)], realizing a series of novel three-dimensional and quasi-three-dimensional nanostructures [Nanophotonics 7, 1637 2018); APL Photonics 3, 100803 (2018)], carring out new optical application research, including deformable stereoscopic supersurface [Advanced Materials 32, 1907077 (2020)], second harmonic chiral radiation supersurface [Laser & Photonics Review 14, 2000085 (2020)] and so on. These research works have realized the integration of the concept of kirigami / origami technology and scientific thoughts at the microscale/ nanoscale, gradually developing into a cutting-edge research field with distinctive characteristics.

Figure1: Basic deformation characteristics of microscale / nanoscale kirigami / origami (folding, bending, twisting), graphene kirigami / origami, and stress excitation methods.

The review paper pointed out that the microscale/ nanoscale kirigami / origami deformation has characteristics beyond the traditional three-dimensional microprocess/ nanoprocess methods, such as unique continuous folding, bending and twisting. However, because conventional macro operations are not suitable for microspace/ nanospace, so although the design theory is very mature, the current microscale/ nanoscale kirigami/ origami technology is mainly limited by the deformation excitation method. This is because the essence of microscale/ nanoscale deformation is to use the difference in stress generated in different regions to drive the structure to deform itself. Therefore, to achieve the deformation of kirigami/ origami, the key is to apply an ideal stress distribution to the structure. In response to this problem, the research team has summarized the microscale/ nanoscale stress generation methods, mainly including capillary forces, residual stress, mechanical stress, material stress, ion beam bombardment stress, etc ( Figure 1), all of them can be used as an incentive method for microscale/ nanoscale kirigami/ origami deformation. Each incentive method contains a wealth of comprehensive scientific ideas and technical methods in physics, chemistry, materials, mechanics and other disciplines, and can be designed and optimized through in-depth theoretical understanding.

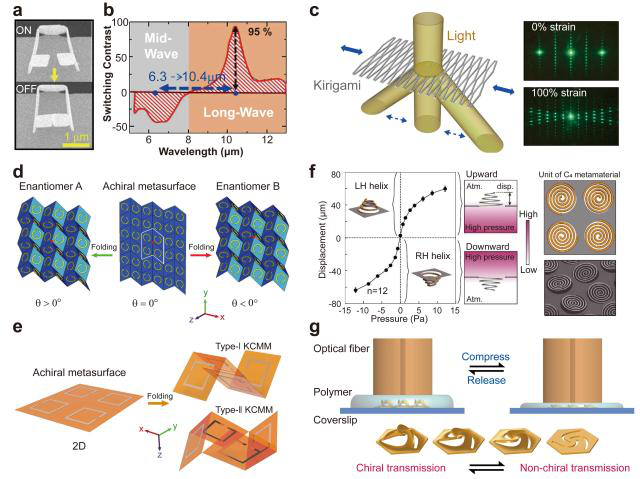

Figure 2: Reconfigurable optical applications based on kirigami/ origami technology

The research team also discussed the potential application in microscale/ nanoscale three-dimensional kirigami/ origami technology. Microscale/ nanoscale three-dimensional kirigami/ origami technology breaks through the limitations of traditional bottom-up, top-down, self-assembly and other three-dimensional processing methods in terms of geometric shape, and can achieve a wealth of three-dimensional deformations, such as folding, bending, stretching and twisting at the microscale/ nanoscale, so it shows great applicapable potential in the fields of two-dimensional materials, biological and optical devices, reconfigurable systems and so on (Figure 2).

The kirigami/ origami technology covered in this review article can provide a simple and effective means for further development, excavation and reshaping of the existing materials' force, heat, electricity, magnetism, light, sound, etc, and is expected to solve many difficult problems in the field of microdevices/ nanodevices. Chen Shanshan, doctoral student of BIT, and Chen Jianfeng, doctoral student of South China University of Technology are co-first authors. Professor Li Jiafang of BIT and Professor Li Zhiyuan of South China University of Technology are co-corresponding authors of the paper. The author thanks Beijing Institute of Technology, Institute of Physics CAS, Massachusetts Institute of Technology, National Natural Science Foundation of China, National Key R & D Program of China, Guangdong Innovation Fund and Beijing Natural Science Fund Foundation and other cooperative teams and projects for their support.

Article information: Shanshan Chen #, Jianfeng Chen #, Xiangdong Zhang, Zhi-Yuan Li * and Jiafang Li *, “Kirigami / origami: unfolding the new regime of advanced 3D microfabrication / nanofabrication with“ folding ””, Light: Science & Applications 9, 75 (2020). (# Is a joint work; * is the corresponding author) Link to the article: https://www.nature.com/articles/s41377-020-0309-9

News Source:School of Physics

Editor:News Agency of BIT

Translator:Zhang Yinuo